6 4 1 when inspection measuring and test equipment is found to be out of calibration any previous inspection and test reports since the last acceptable calibration will be assessed for their validity and recorded in the calibration register tk qf 025.

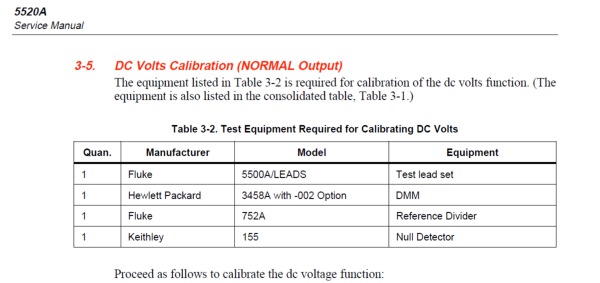

Test equipment calibration procedure.

7 8 calibration procedures 7 8 1 calibration procedures must be application specific and prescribe step by step instructions for calibration of measurement and test equipment or categories thereof.

These shall be prepared internally by another agency the manufacturer or a composite of any of these.

Oppermann is out of print and the majority of content has been updated and published in the publications noted below.

This will help to assure that parts.

The purpose of the data sheet is to record test readings and their variance from optimal values designated in the equipment s mp.

This procedure is designed to be compliance to iso 9001 2015.

During the calibration of certain pieces of equipment a data sheet is filled out if required by the procedure.

Nbs handbook 145 1986 handbook for the quality assurance of metrological measurements by john k.

Texas quality assurance is happy to provide you with a free procedure calibration of measuring.

Calibration procedure for measuring testing equipment 1 0 purpose this procedure provides specific instructions for the verification calibration and maintenance of mechanical and electrical measuring and testing equipment to ensure its proper functioning and continued accuracy.

Reference documents 3 1 xxx quality manual 3 2 procedure for quality control 4.

Scope this procedure applies to the laboratory equipment used by the laboratory of xxx.

6 5 all measuring and test equipment both company and personal used in production or.

Hb 145 was developed as a source of calibration procedures for weights and measures laboratories and covered mass length and volume calibrations for field.